The rating of capacitor bank is as per system / customer requirement

PRODUCT RANGE

Rated Output: 100 KVAR to 50000 KVAR

Rated Voltage: 1 KV to 765 KV

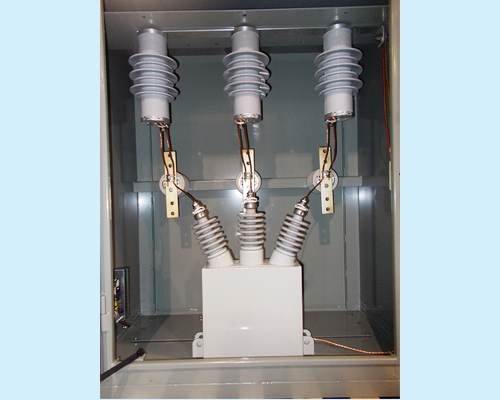

We offer a full system analysis, design, supply, testing & installation of MV/HV capacitor bank with associated equipment’s / switch gears.

MV / HV capacitor bank consist of: